What Happens During a Roof Inspection That Homeowners Never See

What Happens During a Roof Inspection That Homeowners Never See

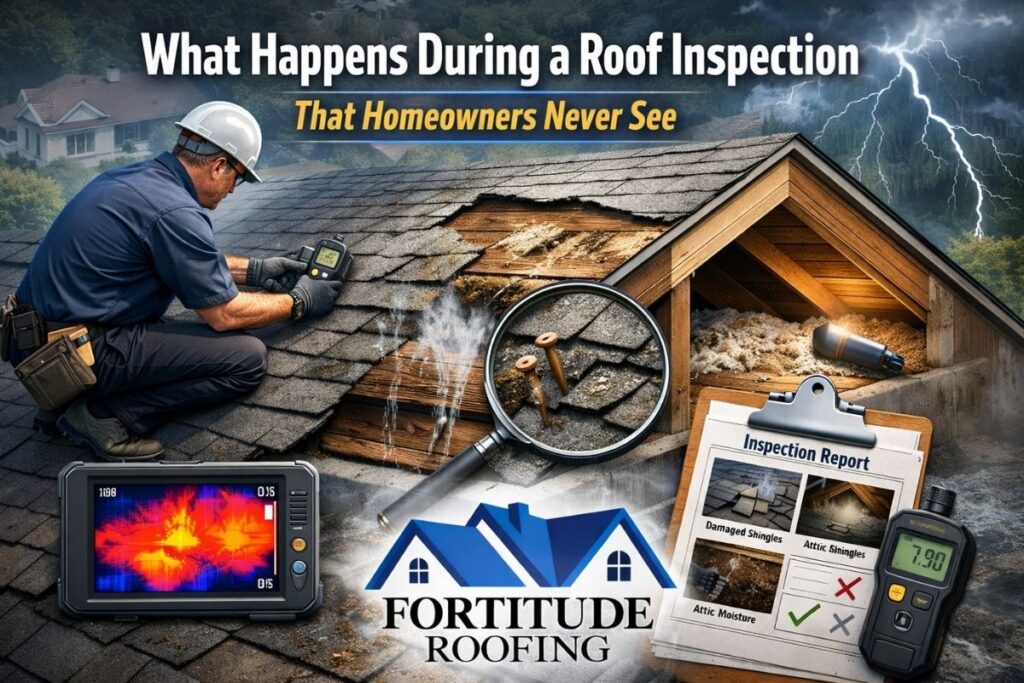

Most homeowners think a roof inspection is a visual walk-around: look for missing shingles, check the flashing, and call it a day. A professional inspection—especially when storm damage, leaks, repairability, or insurance questions are involved—goes deeper.

The best inspections are diagnostic. They evaluate the roof as a system, test assumptions, and document findings in a way that supports a clear repair or replacement decision.

This guide explains the behind-the-scenes evaluation steps homeowners rarely see, and why inspection quality matters as much as timing.

Fortitude Roofing serves Carteret, Craven, Onslow, Pender, Brunswick, and New Hanover counties.

Quick Answer: What Do Professionals Check During a Roof Inspection?

A professional roof inspection typically includes more than visible shingle checks. It may involve:

- diagnostic testing (including flex and seal checks where appropriate),

- fastener and attachment evaluation,

- moisture assessment in the attic and interior,

- pattern analysis across roof slopes,

- flashing, ventilation, and system-detail review,

- and code/manufacturer considerations that affect repair feasibility.

A good inspection produces evidence and a defensible conclusion—not just an opinion.

Why “Visual Only” Inspections Miss Important Problems

Many roof failures are not obvious from the ground:

- wind can break seals without removing shingles,

- small punctures can leak intermittently,

- moisture can travel before staining appears,

- poor ventilation can accelerate aging without obvious exterior symptoms,

- repairs can be “possible” but not reliably restorable as a system.

That’s why professional inspections use multiple checks to identify root cause and repairability—not just symptoms.

Behind-the-Scenes Evaluation: What Pros Do That Homeowners Don’t See

1) Flex Testing and Brittleness Assessment (When Appropriate)

Flex testing is a field method used to assess whether shingles have become too brittle to repair without collateral damage. It can help answer questions like:

- Can shingles be lifted to replace damaged pieces without cracking surrounding materials?

- Will a “spot repair” create new failure points?

Why it matters: A roof can be theoretically repairable but practically unrepairable if repairs require disturbing brittle, aging shingles that will not reseal reliably.

(Note: Responsible inspectors apply this carefully and document it—overaggressive handling can cause damage.)

2) Fastener Checks and Attachment Reality

Many performance failures are installation- or attachment-related. A professional may evaluate:

- nail placement (too high, too low, through the seal line),

- over-driven or under-driven nails,

- missed decking or insufficient deck penetration,

- signs of fastener back-out in specific zones,

- attachment issues around edges and transitions.

Why it matters: Fastener problems can mimic “storm damage” or can explain repeated blow-offs and leaks in high-wind coastal conditions.

3) Moisture Assessment: Attic, Decking, and Interior Clues

Leaks are rarely straightforward. Water can enter in one location and show up somewhere else. A strong inspection often includes:

- attic inspection for staining, mold, and wet insulation,

- decking evaluation for discoloration, rot, or delamination,

- ventilation condition review (intake/exhaust balance),

- interior moisture patterns to triangulate entry points.

Why it matters: Moisture findings can confirm active leaks, reveal chronic condensation issues, and separate storm-driven events from long-term deterioration.

4) Pattern Analysis Across Slopes (System-Level Diagnosis)

Professionals don’t only count damaged shingles. They evaluate whether the distribution makes sense:

- windward vs leeward differences,

- ridge/edge concentration where uplift is highest,

- slope exposure and turbulence zones,

- scatter across multiple facets vs single-zone damage.

Why it matters: Patterns help distinguish sudden storm-related damage from normal wear and tear and can influence repairability decisions.

5) Flashing and Detail Review (The Failure Zones)

Many leaks come from roof details rather than the field shingles. Inspections often focus on:

- step flashing at walls and chimneys,

- pipe boots and vent penetrations,

- valleys, skylights, and transitions,

- drip edge/eave details and kick-out areas where applicable,

- prior repair zones and sealant misuse.

Why it matters: A roof can look “fine” from a distance and still leak from one failed detail. A professional inspection targets the high-risk zones first.

6) Code and Manufacturer Considerations (Repair Feasibility)

A professional evaluation often includes a repair feasibility check:

- Will the repair method comply with manufacturer requirements?

- Will ventilation changes be required to meet installation specs?

- Are underlayment/flashing details compliant for the work being proposed?

- Would bringing one area into compliance force broader scope?

Why it matters: Even if a repair is possible, it may not be acceptable if it creates manufacturer noncompliance, performance risk, or scope that can’t be isolated cleanly.

What a High-Quality Inspection Produces (Deliverables That Matter)

If you want to judge inspection quality, focus on outputs—not confidence.

A strong inspection typically provides:

- slope-by-slope photo documentation (wide + close),

- a clear explanation of observed conditions vs conclusions,

- identification of the likely failure mechanism (wind, impact, detail failure, condensation),

- repair vs replacement rationale tied to system integrity,

- a written scope recommendation aligned to performance and compliance.

A weak inspection often produces only a verbal opinion and a few generic photos.

When Timing Matters (And When Quality Matters More)

Timing matters because storm indicators can change:

- displaced shingles can reseat,

- seals can partially re-bond in heat,

- temporary repairs can mask evidence,

- moisture patterns can evolve.

But inspection quality matters as much as timing because a poor inspection performed “fast” still misses root causes and produces decisions you’ll pay for later.

FAQs

Do roof inspectors actually test shingles or just look at them?

Many professional inspectors do more than look. They may perform careful flex/seal checks, evaluate fasteners and details, and validate findings with attic or moisture assessment—especially when repairability or insurance questions are involved.

Why do some inspections miss storm damage?

If the inspection is ground-only, lacks slope-by-slope documentation, or ignores pattern and seal integrity, subtle wind damage can be missed even when it exists.

What’s the most important part of a roof inspection report?

Clear documentation: slope-labeled photos, specific observations, and a defensible explanation of why the recommended scope restores performance and complies with requirements.

Final Takeaway

Professional roof inspections involve more than visual checks. The behind-the-scenes work—flex testing, fastener evaluation, moisture assessment, pattern analysis, and code/manufacturer considerations—is often what separates a reliable conclusion from a guess. Inspection quality matters as much as inspection timing.

Fortitude Roofing Service Area (Coastal NC)

Fortitude Roofing serves homeowners across coastal North Carolina, including Carteret, Craven, Onslow, Pender, Brunswick, and New Hanover counties—such as Wilmington, Hampstead, Surf City, Jacksonville, Morehead City, Beaufort, Emerald Isle, Leland, Southport, and Oak Island.

Author and Review

Reviewed by: Fortitude Roofing (Coastal NC)

Educational content only. Coverage decisions depend on policy language, endorsements, and carrier determinations.