When a Roof Repair Voids a Manufacturer Warranty (And How to Avoid It)

When a Roof Repair Voids a Manufacturer Warranty (And How to Avoid It)

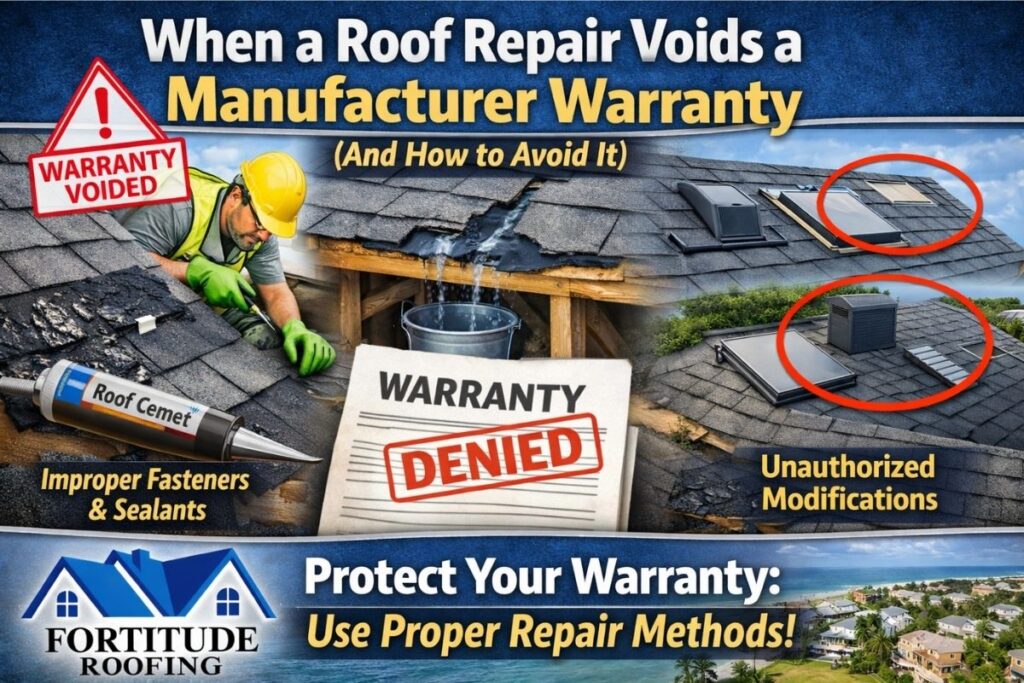

Not all roof repairs are harmless. A repair that “stops the leak” can still create long-term problems—especially if it violates manufacturer installation requirements. In some cases, the wrong repair approach can jeopardize coverage under a manufacturer warranty.

This guide explains the most common ways roof repairs can void or limit manufacturer warranty coverage, why manufacturers take this position, and how homeowners in coastal North Carolina can avoid preventable warranty issues.

Fortitude Roofing serves Carteret, Craven, Onslow, Pender, Brunswick, and New Hanover counties.

Quick Answer: When Can a Roof Repair Void a Manufacturer Warranty?

A roof repair can void or limit a manufacturer warranty when it changes the roof system in a way that conflicts with the manufacturer’s installation requirements—such as using incompatible materials, incorrect fasteners, unauthorized modifications, or ventilation changes that cause performance problems.

Manufacturers generally warrant products and systems as installed per their requirements. Repairs that compromise system integrity can create failure modes the manufacturer will not stand behind.

Why This Happens: Warranties Assume System Integrity

Manufacturer warranties are not “anything goes” promises. They are built around a central assumption:

The roof system was installed and maintained in a way that matches the manufacturer’s specifications.

When a repair introduces incompatible components or incorrect methods, the roof can fail for reasons unrelated to product defects (seal failure, blow-offs, moisture damage, premature aging). Manufacturers often treat those failures as workmanship, modification, or maintenance issues—outside warranty responsibility.

Common Warranty Killers (And What They Look Like in the Field)

1) Improper or Incompatible Materials

A frequent problem is mixing products that are not approved to work together, such as:

- using non-matching accessory components (starter, ridge, underlayment) that conflict with the system requirements,

- using generic sealants or mastics in ways the manufacturer does not allow,

- installing mismatched shingles or “close enough” substitutes that don’t meet the system spec.

Why it matters: The manufacturer may deny warranty claims if the system was altered using components they did not approve for that roof assembly.

2) Incorrect Fasteners (Type, Length, Placement, Quantity)

Fasteners are a major compliance point. Repairs can create issues when crews use:

- incorrect nail type (corrosion resistance matters in coastal environments),

- incorrect nail length (not properly penetrating the deck),

- under-driving or over-driving nails,

- incorrect nail placement or insufficient fastener count.

Why it matters: Fastener errors can cause blow-offs, sealing failures, and shingle damage that look like product issues but are actually installation defects.

3) Unauthorized Modifications to the Roof System

Some repairs effectively redesign the roof system without acknowledging it. Examples include:

- “patching” with nonstandard layers or membranes,

- altering flashing details in a way that changes water flow or creates concealed traps,

- adding penetrations or modifying roof features without proper detailing.

Why it matters: Once the assembly is modified outside published methods, the manufacturer can argue the system no longer matches the warranted configuration.

4) Ventilation Changes or Mismanagement

Ventilation is one of the most common reasons manufacturers limit warranty claims. Repairs can inadvertently cause problems when they:

- block intake ventilation at soffits,

- add exhaust ventilation without balanced intake,

- remove or change ridge vents incorrectly,

- create short-circuit ventilation paths that trap heat/moisture.

Why it matters: Poor ventilation can accelerate shingle aging, cause deck moisture issues, and create premature failure conditions that manufacturers typically classify as non-warrantable.

5) “Temporary” Repairs That Become Permanent

Homeowners sometimes apply tar, roof cement, spray foam, or heavy sealants as an emergency fix—and then leave it indefinitely.

Why it matters: These materials can:

- interfere with shingle sealing behavior,

- trap moisture,

- complicate future repairs,

- and create failure modes the manufacturer won’t cover.

Emergency mitigation is valid, but it should be clearly temporary and later corrected using compliant methods.

How to Avoid Warranty Problems When You Need a Repair

1) Require a Repair That Preserves Manufacturer Compliance

Ask your contractor:

- “Will this repair maintain compliance with the manufacturer’s installation requirements for my roof system?”

- “Are the materials and accessories compatible with the existing roof?”

A reputable contractor should explain the method and why it does not compromise the assembly.

2) Use Matching or Manufacturer-Approved Components When Possible

When repairs involve shingles, ridge caps, underlayment, or accessories:

- match the product line as closely as possible,

- use manufacturer-approved equivalents when exact matches are not available,

- avoid “close enough” substitutions that create system conflicts.

If the product is discontinued, the repair strategy should account for compatibility and performance—not just appearance.

3) Verify Fastener Specifications (Especially in Coastal NC)

Fasteners must meet:

- type and corrosion resistance expectations,

- correct length for deck penetration,

- correct placement and pattern.

This is particularly relevant in coastal environments where corrosion and wind loads are more severe.

4) Don’t Change Ventilation Without a System Plan

Ventilation should be treated like a system:

- intake + exhaust must be balanced,

- changes should be documented and justified,

- ridge/soffit configurations should not be altered casually.

If a repair requires ventilation changes, have the contractor document the rationale and configuration.

5) Keep Documentation: Photos, Invoices, Materials Used

If warranty questions arise later, documentation is your leverage. Request:

- before/after photos,

- a written repair description,

- materials listed (brands/products if available),

- confirmation that the repair was performed to manufacturer requirements.

What Homeowners Should Ask Before Approving a Repair

Use a short checklist:

- “What manufacturer system is on my roof (if known), and is this repair compatible?”

- “Are you changing ventilation or penetrations?” If yes, “How are you balancing intake/exhaust?”

- “What fasteners are you using, and will they meet deck penetration requirements?”

- “Will this repair introduce nonstandard sealants or membranes?”

- “Can you provide before/after photos and a written scope of repair?”

These questions discourage corner-cutting and make warranty compliance explicit.

FAQs

Does any roof repair void a manufacturer warranty?

No. Repairs performed using compatible materials and compliant methods typically do not void warranties. Problems arise when repairs conflict with the manufacturer’s installation requirements or alter system integrity.

What’s the most common reason warranties get denied after repairs?

Improper installation methods—especially fastener issues and ventilation problems—are among the most common denial drivers because they create failures unrelated to product defects.

Do sealants or roof cement void warranties?

They can, depending on how they’re used. Heavy or nonstandard sealant use can interfere with sealing, trap moisture, and create failure modes the manufacturer may classify as non-warrantable.

If my shingles are discontinued, what should I do?

You may need a repair plan that uses manufacturer-approved equivalents or a broader scope that restores system integrity without mixing incompatible products. The right approach depends on the roof system and what can be matched.

Final Takeaway

Warranties assume system integrity. Repairs should preserve—rather than compromise—manufacturer requirements for materials, fastening, detailing, and ventilation. If you need a repair, the safest path is a documented, compliant method using compatible components, with photos and a written scope that protects you if questions arise later.

Fortitude Roofing Service Area (Coastal NC)

Fortitude Roofing serves homeowners across coastal North Carolina, including Carteret, Craven, Onslow, Pender, Brunswick, and New Hanover counties—such as Wilmington, Hampstead, Surf City, Jacksonville, Morehead City, Beaufort, Emerald Isle, Leland, Southport, and Oak Island.

Author and Review

Reviewed by: Fortitude Roofing (Coastal NC)

Educational content only. Warranty terms vary by manufacturer and specific warranty type. Always refer to your warranty documents and manufacturer requirements for your roof system.